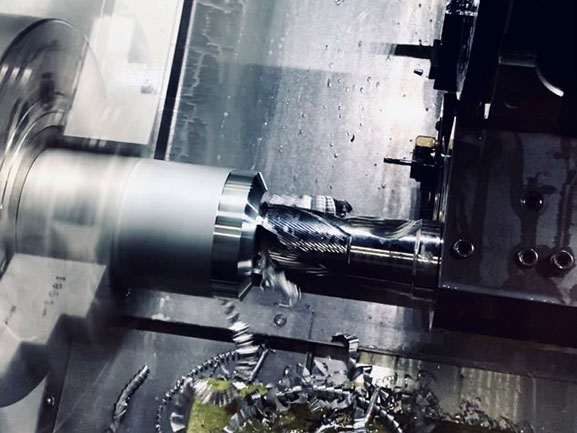

Turning and milling

Orders in the field of turning and milling are carried out with the help of modern lathes and milling machines, thus guaranteeing reliability and precision of implementation.

The conventional turning service is carried out using DOOSAN lathes together with a bar feeder.

Process parameters:

- diameter of passage over the bed: 600 mm

- diameter of passage over the bottom bracket: 400 mm

- maximum turning diameter: 300 mm

- maximum turning length: 510 mm

- spindle rod diameter: 65 mm

We provide milling services using MIKRON and BRIDGEPORT machining centers.

Process parameters:

- displacement X: 860 mm

- displacement Y: 560 mm

- displacement Z: 600 mm

Turning and milling

- Srebrna Góra

- Wrocław

- Wałbrzych

- Legnica

- Jelenia Góra

- Opole

- Częstochowa

- Katowice

- Kraków

- Rzeszów

- Przemyśl

- Lublin

- Poznań

- Łódź

- Warszawa

- Białystok

- Olsztyn

- Elbląg

- Toruń

- Gdańsk

- Gdynia

- Szczecin

- Bydgoszcz

- Zielona Góra

We operate locally, but we think globally.

Thousands of satisfied customers. We have been trusted by the world's largest companies. You do not believe? See for yourself. Please contact our sales department.

Values

Our values not only define our identity but also shape company’s culture and impact our business strategy.

Reliability

Integrity

Professionalism

Transparency

Partnership